Southern Wind 108

Southern Wind's latest 108-footer is a all-high tech oceanic beauty

Remember those early sailing superyachts... high-chested, heavy, aluminium and sometimes even welded steel hulls? Yet not many years later the fact that Southern Wind's latest 108-footer is an all-carbon, all-high tech oceanic beauty, one that also screams high performance is almost to state the obvious...

At the Southern Wind Shipyard in Cape Town the first of a new generation of yachts is now taking shape. It’s a case of evolution not revolution, in keeping with the brand’s carefully calibrated and distinctive core DNA. But while the visible differences between the Southern Wind 108 and its predecessors might seem subtle at first, this is a significant milestone for the shipyard. It’s their first model conceived and engineered from the outset as a diesel-electric hybrid.

‘A core feature of Southern Wind’s new generation of smart custom yachts is the versatility to have several configurations of propulsion systems, keels and sailplans,’ Farr Yacht Design’s Jim Schmicker explains. ‘The biggest challenge for us as the naval architects was to design a hull that would perform well at any selected displacement in the anticipated range.’

Depending on the rig, keel and drivetrain options selected by an owner, the design weight can vary by almost six and a half tonnes – and that’s before you start to consider differences in the weight of the hull itself, the interior fit-out and the payload of systems, equipment, tankage and so on, all of which can also be quite considerable.

‘The platform is the starting point for discussions with the owner’s team,’ says Andrea Micheli, chief commercial officer at Southern Wind. ‘Tried and tested solutions are always on the plate but when an owner wants something truly unique we have the capability to customise extensively.’

Southern Wind’s “Smart Custom” approach offers a lot more scope for customisation than most semi-custom builders can allow, so the highly versatile platform created by Farr for the 108 adds a huge amount of potential value. ‘The desired versatility in the hull shape is achieved with a bit more slope in the underbody at the ends, slightly lifting the turn of the bilge aft and making the section shape through the waterline straighter,’ Schmicker says. ‘The SW108 presents as less angular than her immediate predecessors, the SW105 and SW96.’

At the start of the design process for the 108’s platform, the range of displacement was clearly defined and several configurations were developed in parallel, Schmicker explains. ‘For the naval architecture the version with the largest sailplan and the greatest righting moment is the important “end stop.” This version sits deepest in the water and the shaping of the waterline endings are made finer to produce clean and efficient flow with immersion at its deepest. Lighter flotations were anticipated and to ensure that those versions also have efficient waterline endings the volume immediately inboard of those waterline endings is increased.’

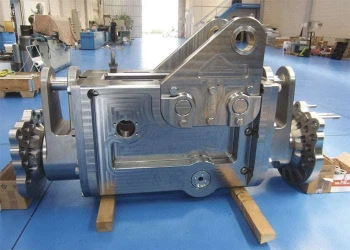

Drawing experience from the recent design loop of SW96-04 Nyumba, which has a similar BAE HybriGen propulsion system, Southern Wind optimised the position of the 108’s internal structure to suit the hybrid drive layout, as Yann Dabbadie, the shipyard’s technical manager, explains: ‘This allowed us to integrate the high-voltage batteries lower down in the bilge and rationalise a more central high-voltage distribution board, cabling and cooling system,’ he says. ‘All this makes for a more compact system, easier to access and with a lower centre of gravity.’

The options available to owners include ways to boost the sustainability of the build, along with many other parameters. ‘‘Changing the outer skin of the hull to glass/Aramid is possible and would keep the seaworthiness of the yacht but will add some weight with a very negligible impact on performance and some tangible saving on the carbon footprint of the composite construction,’ says Marco Alberti, chief executive at Southern Wind. ‘We advise our clients by presenting various options which show a cost and weight assessment but also consider the implications of righting moment and comfort. Our aim is always to assist the client in his choices and build the yacht to his expectations. During this process we check bulb weight, displacement and righting moment, and we do an optimisation loop with Farr Yacht Design. After which we inform the client and discuss what variations and effects each of his or her choices would have.’

The owners of SW108-01 took things very close to Schmicker’s end stop, which gave the shipyard, Farr and Nauta a great opportunity to flex their skills. ‘It was a pleasure taking them through the design process and evaluating the many configurations available,’ Schmicker says. ‘They were keen on the hybrid propulsion system which adds weight and some propeller installation drag. Through several design loops the sail area and keel weight were fine-tuned to the owners’ goals for performance and also for stability and sail carrying power. To achieve the desired light wind performance, sail area was increased by seven per cent as well as righting moment by 18 per cent through fitting a larger bulb on the lifting keel compared to a SW108 with a standard propulsion system. In light winds, 12kts boatspeed can be achieved. Reaching and downwind in a breeze, 20kts is expected.’

To achieve the opposing goals of maximising performance while also having the option of hybrid propulsion (which is heavier mainly due to the generous energy storage), weight savings had to be found. ‘The boat makes ample use of titanium not just on stanchions and mooring cleats but also all the way up the mast and down to the underwater anchor mechanism,’ Dabbadie explains. ‘This will also be the first yacht to feature the new Harken 9T Air captive winch. Together with a full carbon construction and high-modulus carbon mast, the weight saving is close to a ton. And in their quest for the optimum setup the owners have chosen a deep lifting keel that lowers the centre of gravity by 40cm whilst keeping control on the overall weight.’

The mast is taller than standard with a lightweight rack boom. ‘The jib and staysail are both with structured luffs for better performance and weight saving,’ Dabbadie says. ‘Versatility was also in the original brief so the cruising configuration of pinhead mainsail, fixed backstay and checkstays can be changed for racing to a square top main with runners and deflectors, controlled by the aft winches.’

A key requirement in the design brief was to optimise SW108-01 for long-range ocean passages with the owners on board. ‘Under sail the yacht will be able to regenerate sufficient electrical power for the comfort of everyone on board with minimal fossil fuel consumption,’ project manager Christophe Harvey explains. ‘The HybriGen system allows very brief battery charging sessions so it’s possible for most of the time sailing or at anchor to be in full silence with no emissions.’ Ultra-efficient refrigeration and AC systems have been fitted, with built-in redundancy and the ability to operate worldwide, in tropical water temperatures above 30°C and also near 0°C in high latitudes.

The deck plan and interior layout, both by Nauta Design, are also fully optimised for ocean cruising, Harvey says. ‘The deck, while showing a sleek line is very protective with its lower guest cockpit that will welcome owners, guests and children in a very well sheltered and safe space behind the coachroof and dodger. The foredeck was also a focus of the designers’ attention with four winches at the mast step to safely handle all manoeuvres and a huge deck locker designed by the yard.’

‘Our deck design achieves a balance in offering big, comfortable and safe spaces,’ says Massimo Gino, founding partner of Nauta Design. ‘Spaces that can be transformed from 20 people eating in comfort around the cockpit tables into 16sqm sunbeds, or into a twin cockpit for a big cocktail party. The manoeuvring areas are clearly separated from the cockpit and are designed for a cruising-racing crew with safety as a main priority.’

The owners of SW108-01 chose the GT Series deck and transom designs, which Nauta has evolved from those of SW105 Taniwha and SW96 Nyumba, and then worked with Gino’s team to customise them. ‘The colour and material scheme decisions drove several finetunings of the geometry to emphasise the design and the character of the deck,’ Gino says. ‘With Southern Wind we developed several transom/beach club and garage solutions. When the yacht is at anchor, the twin-fold transom concept gives guests on board a direct connection with the sea. By opening the aft portion of the deck together with the transom door, the swim platform doubles its surface area.’ The garage is designed to fit a 5.05m diesel jet tender.

As the hull takes shape in Cape Town, at Nauta’s design studio in Milan a great deal of work is now focused on the fine details of the yacht’s interior design. ‘We collected a very clear brief from the owners,’ Gino says. ‘Listening closely, as per our experience, is the first exercise in every design process. Immediately after this kick-off meeting, we penciled down some key points. I think that this was the first of several moments in which we and the owners shared a common view of the interior style. Thousands of details that must live together in a clean and simple way.’

‘Ambitions are very high,’ he explains. ‘But allow us to say that the common view of style solutions is making this interaction flow easily with reciprocal satisfaction. Lighting, finally, has an important role on the interior design, with the natural light coming from generous hull windows and skylights and a conscious use of artificial lights allows to create the desired ambience for every occasion on board.’