Tech and design tools combined to phenomenal effect in the Gunboat 80

Tech and design tools combined to phenomenal effect in the Gunboat 80

Technology and design tools from the America’s Cup, Ultime trimarans and Imocas have been combined to phenomenal effect in the Gunboat 80

The Gunboat 80 belongs in a different category from any other sailing yacht. On one hand it offers thrilling full Grand Prix performance, sailing faster than the wind from a mere four knots upwards, reaching maximum boat speed of over 30kts when cracked off the breeze, and will average well over 350 miles daily on an Atlantic crossing. Yet it’s also a superyacht with space, comfort and amenities that can only be matched by 100ft monohulls.

At this level of the market, owners naturally want a vessel that’s precisely tuned to how they intend to use it. However, custom builds require owners to have their own large and skilled team, while the entire project duration can be as much as six years. In an era in which both yacht design and sailing systems are advancing at a relentless pace, that's a huge lead time.

By contrast, Gunboat’s very flexible “box rule” customisation concept enables owners to create a tailored high-tech boat, with state-of-the-art design, materials, engineering and systems, in a typical timeframe of only two years. While the shape of the structure, including main bulkheads is fixed, almost everything else can be modified.

The first two boats – both for hugely experienced, well-known serial owners – illustrate how wide the range of possibilities is for this platform. Boat number one is Lord Irvine Laidlaw’s Highland Fling XXVll, which will be used solely for coastal racing in Maxi Multihull regattas in the Mediterranean and Caribbean. It therefore has a very stripped out interior and is optimised to fly a hull in around 12kts of true wind.

The second boat is for a totally different purpose – she will be a family cruiser for an equally well-known owner, who has a decorated history of campaigns, including the GC32, M32 and Melges 32 classes.

Both boats have a common core design developed by VPLP’s racing division, using the same tools and processes as the latest Imoca 60s and Ultime trimarans. They also share sail handling and performance technologies developed for the last two America's Cups.

Highland Fling, which launched in summer 2023, is raced with a 10-12- strong professional crew and is fitted with huge eight-metre asymmetric daggerboards. The ability to raise and lower the boards, even at speeds of more than 20kts, was a key priority for the team. To overcome the huge loads involved, they looked to the high-tech reciprocating roller bearings of the systems employed by the AC72s and the AC50s. Designers for those bearings were asked to redevelop the concept for 80-01.

Xavier Guilbaud, VPLP design

Building on the success of the 68, the Gunboat 80 is the best mix of the two worlds between racing and cruising. The boat has been designed and engineered with a constant eye on weight optimisation as weight is key to performance.

The construction uses all our racing boat experience with prepreg carbon. The core material is Corecell foam for hulls and wetdeck and honeycomb core for deck, cabin top and all interior structure.

Together with long asymmetric boards and a high aspect ratio rig, she is a weapon on all points of sail.

The boat was engineered to full righting moment as the aim is to fly the windward hull when racing. The powerful hulls have been optimised for high speeds with a tense keel line and boxy sections.

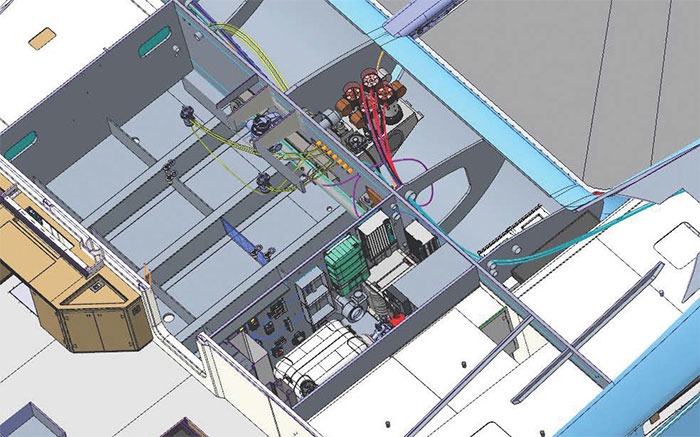

The deck layout is organised around six big hydraulically controlled winches. Like the 68, the Gunboat 80 has a forward cockpit where all the halyards, reefing lines, daggerboard manoeuvres, tacklines and furling lines are dispatched on two hydraulic Harken 1125 winches.

The flat foresails’ sheets come to primary winches on the top of the coachroof just next to the side helm stations where the driver, the trimmers and the navigator are next to each other during races (80.01). They communicate with the forward cockpit using headsets.

On top of that, 12 hydraulic cylinders are used for different controls around the boat such as mainsail sheet and traveller, flat sails inhaul, outhaul and tweaker, mast rotation, cunningham and daggerboard control lines. These rams are controlled in the forward cockpit or at both helm stations and also have wireless remote controls.

Highland Fling XVII, hull one of the series, is clearly focusing on racing due to her owner’s programme and has therefore been even more optimised for that. The interior is minimalist and the deck layout is optimised for racing around the cans with a crew of 12 professional sailors. Also, the sail wardrobe is optimised for rating certificate reasons.

Having been on board during the Maxi Worlds in Porto Cervo in early September last year, I was quite impressed with the level at which the boat was sailed, after just a few days of training since her launch. The boat performed beautifully with still a lot of potential yet to tap, and has given satisfaction to her owner and is very promising for the future. We’ll be looking to see her on the racecourse in the Caribbean and Med circuits.

Hull #2 of the series, currently under construction with a summer 2024 launch date, is family cruising orientated. Having said that, being a race addict himself, the owner was quite keen to have a fast boat to play with.

The rudders are liftable in order to have access to shallow water moorings. We have also added elevators to the rudders (T-rudders), not so much for added performance, but more for comfort at sea as they allow to absorb the motion.

As part of our research and development programme, we have created our in-house dynamic simulator that we use, not only to better understand our boat’s behaviour in waves, but also to benchmark configurations and geometries of appendages on our Ultim trimarans and Imocas.

Typically on this kind of project, we can offer our customers to simulate their own boat in their own configuration of weight, appendages and sail plan and compare it with another candidate to help them make well-informed decisions.

In this size of boat and budget, this tool, which was originally developed for our racing division, has been very helpful in offering semi-custom options and the ability to adapt to each client.

This is just one example of the overarching philosophy applied by Gunboat - collaborating with top specialists in each field to create the best engineered boat possible. Partnerships in component manufacturing leave Gunboat to focus on its fortés. Hulls, for instance, are built to the same rigorous standards as those of Imoca 60s at Fibre Mechanics in the UK, while decks are moulded by renowned composite specialist Multiplast in Brittany.

‘This approach gives owners the same level of technology they would expect on a custom build,’ says Gunboat’s chief operating officer William Jelbert. ‘But we project manage it, so the client isn’t taking on all the risks. Our specific in-house area of expertise is in composite assembly, systems and interior fitout.’ These are all the complex details that are essential in creating a really great yacht.

Every effort has been made to minimise weight at every stage and construction is of pre-preg carbon, with a high percentage of uni-directional fibres. However, a conundrum in the very high-performance superyacht world is that the hotel systems that make these such comfortable and luxurious places to spend extended periods of time are typically disproportionately heavy.

Gunboat therefore bypassed many traditional marine suppliers for these elements and instead prioritised those in the aerospace sector where feasible. The windows, interior and wiring, for instance, all come from the aerospace industry, helping create a very light displacement for a boat of this size.

In contrast to Highland Fling’s stripped out interior, when she launches in June 2024, 80-02 will have fully fitted accommodation, with an icemaker, oven, generous amounts of refrigeration and air conditioning, plus three VIP cabins, a twin cabin for children and civilised quarters for three crew.

As a result, she’s four tonnes heavier than Highland Fling, at 28 tonnes light ship displacement, and has a maximum payload of six tonnes. Yet this is still a yacht that’s capable of sailing ridiculously fast, with speeds of 30kts possible.

Highland Fling is also engineered for a maximum loaded displacement of 34 tonnes. This opens the possibility of retrofitting a luxury interior and associated systems to give the boat a second life after her all-out racing career. It’s an important safeguard against depreciation. Beyond the vast deck spaces and single-level living arrangements, shallow draught is one of the key attractions of a performance cruising multihull. Boat 80-02 therefore has cassette style lifting rudders that allow the boat to anchor in very shallow water.

VPLP’s in-house dynamic simulator showed that this cruising-optimised Gunboat 80 would benefit from 1.2-metre long T foils on the rudders. In a Caribbean swell these will reduce pitching by around 30 per cent, creating a much more comfortable ride, while simultaneously increasing average speeds.

However, the simulator showed the foils would not benefit Highland Fling, given her predominately inshore/coastal regatta programme, which will mostly be in lighter Mediterranean and Caribbean airs and a smaller sea state in coastal waters. On the other hand, in place of Highland Fling’s complex and high maintenance daggerboard bearings, Gunboat 80-02’s boards have maintenance-free selfaligning bearings. These still allow them to be raised and lowered at boat speeds of up to around 15kts.

Both boats have Gunboat’s trademark forward cockpit, with big hydraulic winches to handle halyards, reefing lines, daggerboards, tack lines and furling lines. Sheets for overlapping headsails lead to coachroof winches to the side of the helm stations, while downwind sails are trimmed from winches aft.

While Highland Fling races with a large, professional crew, for their cruising programme 80.02 has an array of 16 buttons to operate the hydraulics at each helm station. This means one person can lift the daggerboards up and down, sheet both the headsail and main in and out, or adjust the traveller, cunningham tension and so on while helming. The boat also has a self-tacking J3, again with hydraulic sheeting, for the occasions that demand the ultimate in sail handling simplicity when cruising.

‘This is all about the owner experience,’ says Jelbert. ‘Anyone who comes from a performance background will want to be able to tweak rig and sail trim to perfection.’

It comes as no surprise that loads are truly massive on these boats, with up to 60 tonnes of mast compression possible, hence the comprehensive hydraulic systems, including custom elements, of both the first two boats.

Another technology that emerged from the last couple of America’s Cup cycles is structured luff mainsails.

‘There are very few boats flying structured luff mainsails outside the America’s Cup at this stage. Perhaps the best-known example being Flying Nikka, the Mark Mills AC-style foiling Mini Maxi. We believe the Gunboat 80 was the first cruising catamaran utilising this cutting-edge tech’, explains Jelbert.

The advantage is that the bend characteristics of the mast change as cunningham tension is increased or eased. So simply pulling down on the cunningham induces up to 30 per cent more mast bend, which increases the range of depth of the sail at different windspeeds and angles. ‘When we started this project, we were looking at cunningham loads around 1.8 tonnes,’ says Jelbert, ‘but these have increased to six tonnes.’ However, the payback of a structured luff is impressively quick and easy control of mainsail shape.

The boats also benefit from the large amount of recent development in halyard locks and their alternatives. Everything on the Gunboat 80 is held by internal bullet locks – even the mainsail reefs don’t have external hooks. The hydraulics package therefore includes a ram inside the boom at the gooseneck to move the entire boom fore and aft in order to achieve the correct tension for the outhaul and each of the reefs.

Successfully producing yachts with such different goals for experienced and discerning owners vindicates Gunboat’s approach to a very customisable series build concept. Looking from the outside it would be easy to assume this is a rarefied sector of the market, but Gunboat managing partner Benoit Lebizay sees it differently.

He points to the size of the International Maxi Association’s regatta scene, which had more than 100 entries in 2023, and highlights that growth in catamaran sales across the board consistently outperforms every other sector of the market. Yet he says, ‘there was no real alternative on the multihull side to the top end of the performance cruising sector’s Swans, Wallys and Southern Winds.’ Today no other yard comes close to Gunboat in being able to create large performance catamarans that will meet the diverse requirements of a growing number of prospective owners.