As yachts get bigger and bigger, simple tasks become more demanding

As yachts get bigger and bigger, simple tasks become more demanding

As yachts get bigger and bigger, simple tasks become more demanding. When you’re manoeuvring and then securing a superyacht in a tight anchorage there is no such thing as having too much help...

An important part of every voyage and one that is often overlooked is how we manoeuvre when close to land. This includes leaving a slip, a mooring, or even an anchorage. It is here in these settings that not only is skill needed in controlling the propulsion and direction of the boat at low speeds but the techniques and sequence of handling the mooring lines as well. NubeWay has developed two clever solutions to reduce this tension in dockside manoeuvres: the Butler and the Mush automatic folding fairleads.

Done well, dockside manoeuvres look effortless. But when not done well they can create tremendous anxiety and tension – not a good way to start or end any journey – or even spell disaster, resulting in damage to the boat or worse, injury to the crew or the guests.

In the last decade there has been tremendous progress in technology for the easy shorthanded operation of boats under power or sail, with many controls reverting now to hydraulics or electrical power. Line handling has become an automated or semi-automated operation in most applications, allowing for small crews – either professional or the owner and his family or guests – to operate larger and larger yachts. This is a clear trend seen at sailing and boating venues around the world: pleasure yachts are getting larger, faster and they can be operated by fewer crew than ever before.

Yet at marinas and anchorages around the world these same small crews are faced with having to safely secure these large yachts in what can be tight spaces and in possibly rough weather. Safe and successful mooring is vastly easier in conditions of no wind, no tide and flat water. It can quickly become unsafe and potentially uncontrolled when these ideal conditions change. Equipment like bow thrusters and stern thrusters can certainly help, but not all yachts have these devices and there are some circumstances where even with their use there can be elements of risk in docking.

The Butler automated fairlead system helps reduce this risk for large yachts through a simple yet safe and effective line-handling method for the one-person operation of a loaded bow or stern line. The Butler can handle mooring lines of 12-40mm diameter, and is suitable for yachts from about 50 to 80ft in length.

The design resembles regular fairleads installed on the shear rail. It has two inverted L-shaped stainless stems that hydraulically rise from their flush seated positions with the push of a button on the remote. The mooring line is passed through the gap between the stems and led to a winch to take up slack as needed until the correct position is reached.

When the line is ready to be made fast, a button push on the remote lowers the fairlead stems to then pinch the mooring line. Held securely in place by the Butler, the mooring line is now free to be safely tied off on a mooring cleat.

For release, the process is simple: the Butler stems are elevated hydraulically with a button push on the remote, and the line is now free to be eased off as needed.

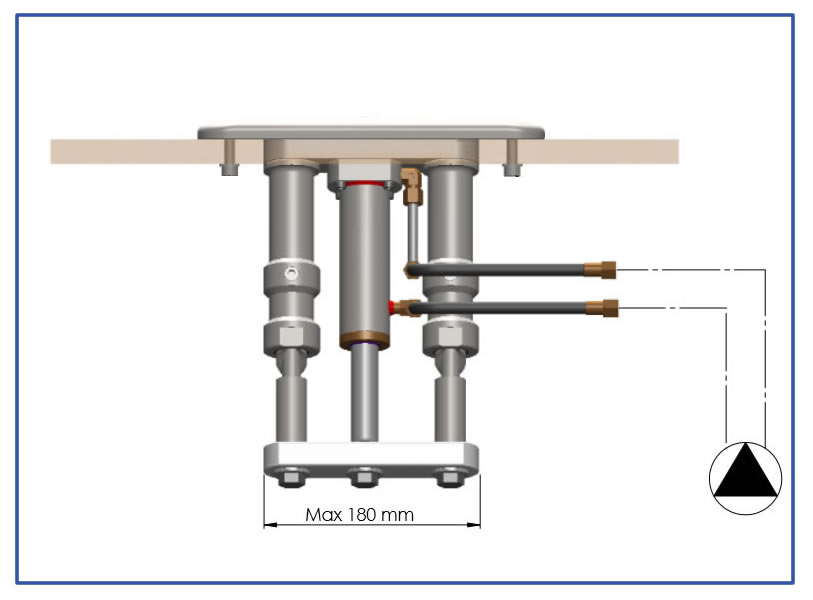

Installing the Butler is relatively easy for either a new or existing yacht with a hollow suitable deck surface or moulded taffrail: an installation depth of 260mm is needed for the hydraulic pistons and the support column, with 180mm of length and width space needed. The on-deck stainless cover plate is low-profile, being only 20mm high for a 280mm length and 80mm width. Working pressure for the pistons is 160 bars for a max pressure of 180 bars. Total weight of the unit is only 8.7kg.

For larger yachts up to 150ft in length, NubeWay has the Mush fairlead system developed to handle larger loads with larger lines and with a larger footprint. On yachts of this size the loads can be exceptionally great, and often require professionallevel expertise to maintain safety. With the Mush system, however, the line-handling becomes easier and safer for one-person use during critical moments within the docking and mooring process.

The circular design of Mush is fundamentally different than that of Butler: the unit is a large diameter circular stem with the mooring line led through its middle when elevated. The stem lifts and retracts hydraulically, and when retracted down it will pinch the line to hold it in place under load, similar to Butler’s operation, but with greater surface area and strength – enough holding power to handle the massive loads that can be encountered when mooring a superyacht.

In use, the process starts with hydraulically lifting the circular fairlead stem from its flush deck position using the remote control, followed by leading the mooring line through the stem. The line is led to a winch where the load can be controlled until the final line position is established. Mush can handle line sizes of 12 to 60mm in diameter.

With use of the remote, the stem is retracted until the line is stopped, and the load can be safely transferred to a cleat or other snubbing device. The circular design of the Mush fairlead allows for a wide variety of angles in line direction.

When ready to release the line, Mush is simply elevated by the remote control and the line is released as needed. Mush can then be retracted to be flush on its mounting, whether this is on the deck or in the cockpit – wherever the best placement requires easy line handling on either power or sail yachts.

The retractable design of Mush is quite attractive for its low profile so as not to interfere with any running rigging on deck while sailing or during other manoeuvres. Installation must be to a strongly reinforced area of the deck or shear rail, but once a suitable location is found the required space is not that large: a hole of 101mm in diameter is needed, with space for four fasteners separated by 146mm. The reinforced mounting plate on deck is slightly larger than this, with the flush plate for the stem being only 30mm above the deck surface when retracted, and rising to 100mm at full extension.

Working pressure in the hydraulic lines is 160 bars, with max pressure being 180 bars with minimum pipe diameter of 4 mm. Total unit weight is only 16 kg.

Both Butler and Mush achieve several important features for the safe and secure mooring of large yachts 50-150ft in length:

safer hands-free operation when transferring mooring line loads

reduces the line-handling operation to one crewman only

no need to hold a hauled line

no need for rolling hitches

during complex mooring operations, lines can be locked into position

anchor-casting can be performed singlehandedly

low-footprint elegant design for the fittings on deck

Both Butler and Mush are designed and manufactured in Italy to the highest standards, with rigorous testing made for resistance to stress, wear and marine corrosion. And both these stylish and innovative products are being distributed by another leader in Italian marine technology: Ubi Maior Italia.